- spécifications du produit

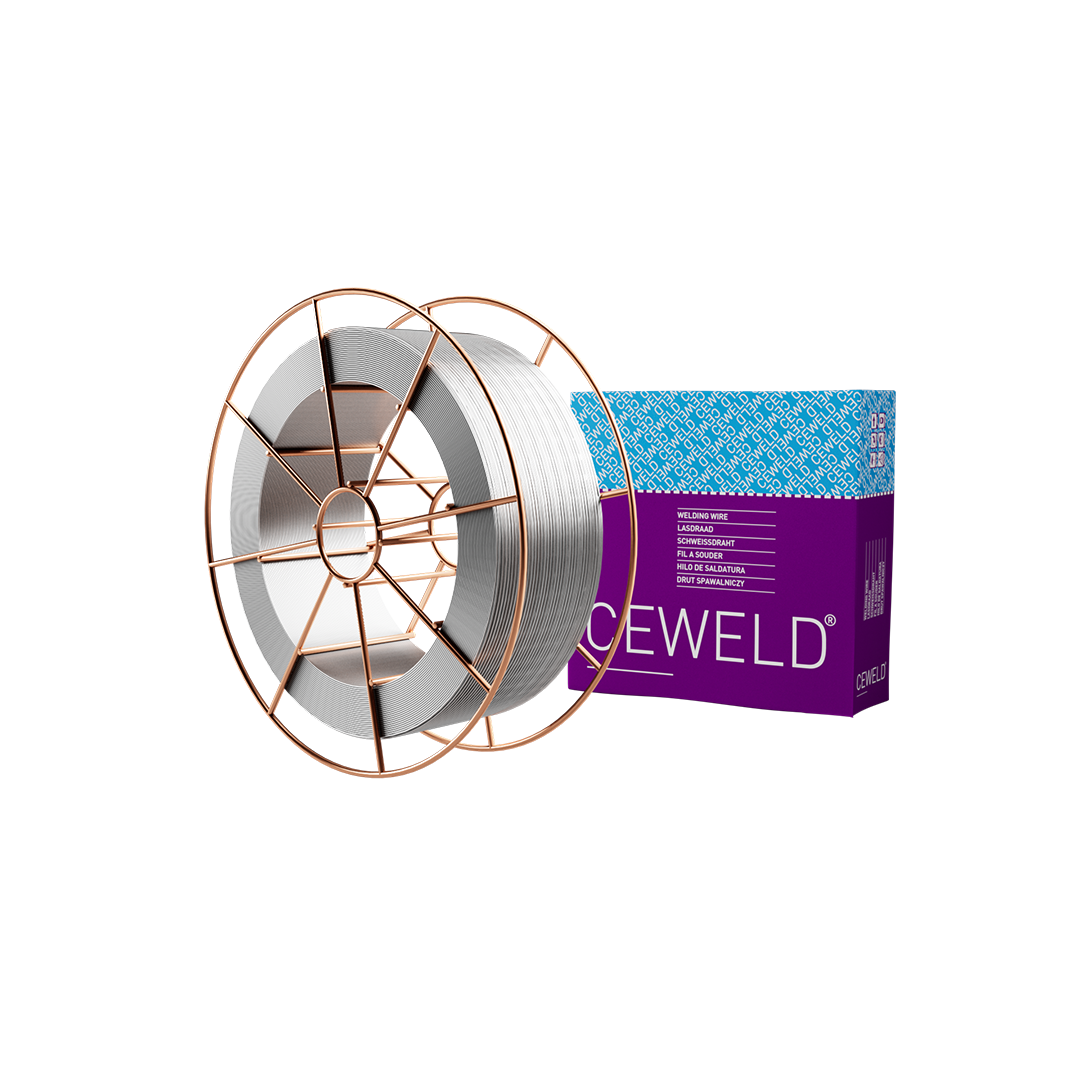

- conditionnement

- demander un devis

Good corrosion and abrasion resistance as required by water turbines in hydropower plants.

13%Cr - 4%Ni - 0,5%Mo Steel

1.4000, 1.4001, 1.4002, 1.4313, 1.4317, 1.4407, 1.4413, 1.4414,

GX4CrNi13-4, X3CrNiMo13-4, GX5CrNiMo13-4, GX4CrNiMo13-4, X 6 Cr 13, X 7 Cr 14, X 6 CrAl 13

ACI Gr. CA 6 NM

| Heat Treatment |

RP0,2 (MPa) |

Rm (MPa) |

A5 (%) |

Impact Energy (J) ISO-V | Hardness |

|---|---|---|---|---|---|

| 0°C | |||||

| As Welded | 800 | 890 | 19 | 67 | 40 HRc |