- productspecificaties

- Verpakkingen

- vraag offerte

The weld deposit offers excellent wear resistance against shocks and abrasion as well. Already the first layer gives excellent results even on mild steel due to the low dilution of the electro slag process. Due to the low dilution with the base metal a hardness exceeding 50 HRc can be achieved already in the first layer. Multiple layers can be applied to obtain full hardness at the final layer. Flux to be used FL 830 ESH

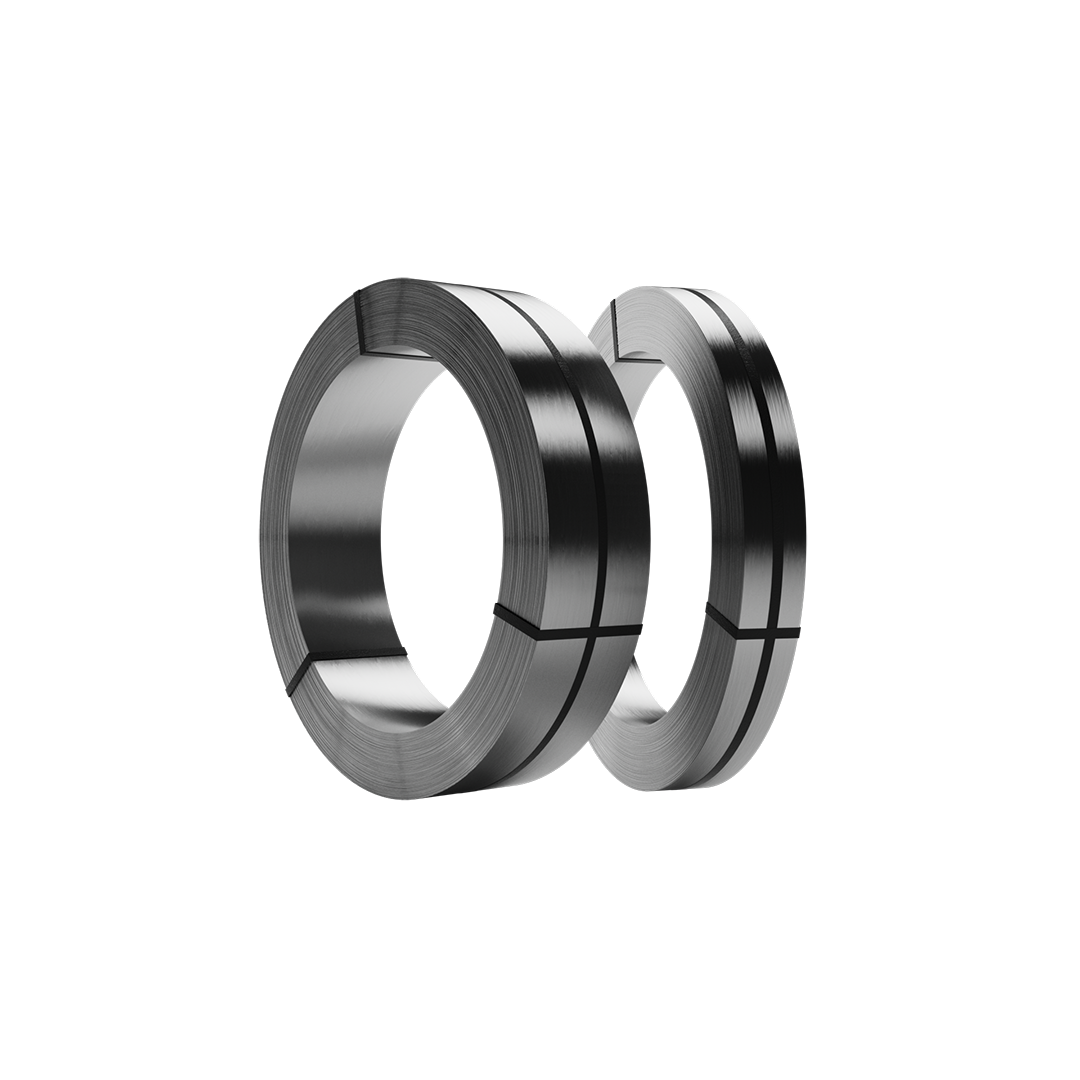

52-58 HRc electro slag and / or submerged arc strip for hardfacing against schock and wear, Rebuilding wornout parts such as screws, chrusher hammers, drive tumblers, chrusher rolls, dredging parts etc..

For ESW welding FL 830 ESHC should be used as welding flux to obtain the results mentioned in this datasheet.

| Heat Treatment |

RP0,2 (MPa) |

Rm (MPa) |

A5 (%) |

Hardness |

|---|---|---|---|---|

| As Welded | 56 HRc |