- PRODUCT SPECIFICATIONS

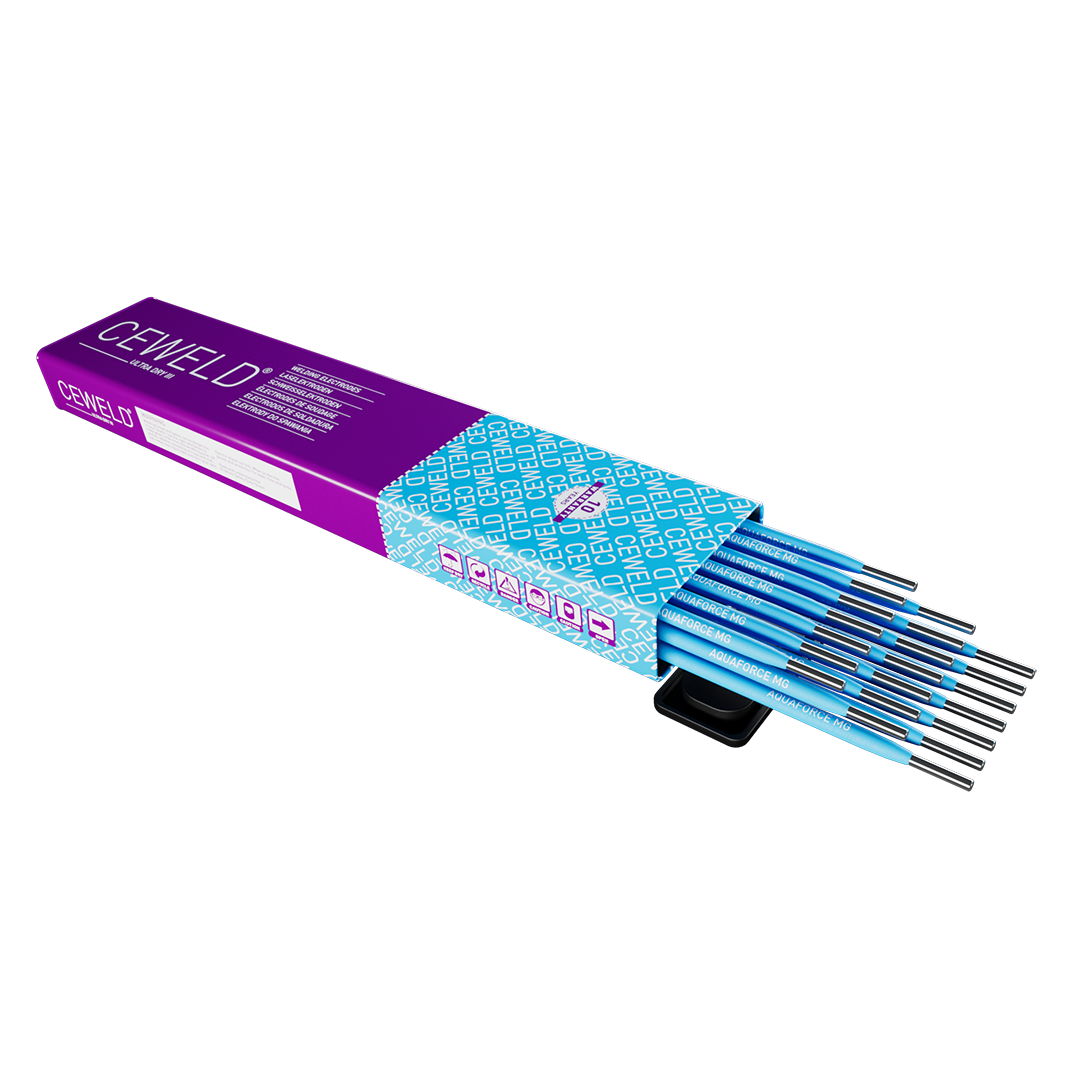

- PACKAGING

- Ask quotation

Welding standard ship steel grades A, B & D in submerged condition according the requirements of AWS D3.6M. Developed for joining anodes to under water objects, plate doubling in ship repair, sealing sheet, pile profiles etc. Tested up to a water depth of 20 m.

Welding standard ship steel grades A, B & D in submerged condition according the requirements of AWS D3.6M. Developed for joining anodes to under water objects, plate doubling in ship repair, sealing sheet, pile profiles etc. Tested up to a water depth of 20 m.

CEWELD AquaForce MG offers a high deposition rate with remarkable welding properties in all positions and is capable of producing beautiful flat weld beads with deep penetration and above all not sensitive for porosity and or inclusions. Filled welds exceeding an A-height of 4,0 mm are easy to achieve in one single layer for high productivity. and can be used in all positions, especially suitable for vertical down (PG) position. The newly designed underwater slag system offers a remarkable self-lifting slag and is double coated to provide maximum resistance to moisture. Excellent mechanical properties with yield strength exceeding 500 MPa in sweet and salt water makes AquaForce MG the preferred choice by professional divers.

Reh ≤420 MPa (60 ksi) ISO 15608: 1.1, 1.2

1.0035, 1.0570, 1.0461,1.0562, 1.4620,1.0565, 1.0345, 1.0425, 1.0481, 1.0308 to 1.0581, 1.0307, 1.0582, 1.0440, 1.0472, 1.0475, 1.0476, 1.0416, 1.0551

S235JR-S355JR, S235JO-S355JO, S235J2-S355J2, S275N-S420N, S275M-S420M, P235GH-P355GH, P355N, P285NH-P420NH, P195TR1-P265TR1, P195TR2-P265TR2, P195GH-P265GH, L245NB-L415NB, L245MB-L415MB, GE200-GE240

ASTM: A 106 Gr. A, B, C; A 181 Gr. 60, 70; A 283 Gr. A, C; A 285 Gr. A, B, C; A 414 Gr. A, B, C, D, E, F, G; A 501 Gr. B; A 516 Gr. 55, 60, 65, 70; A 573 Gr. 58, 65, 70; A 588 Gr. A, B; A 633 Gr. A, C, D; A 662 Gr. A, B, C; A 678 Gr. A, B; A 711 Gr. 1013; API 5 L Gr. B, X42, X52, X56, X60

| Heat Treatment |

RP0,2 (MPa) |

Rm (MPa) |

A5 (%) |

Impact Energy (J) ISO-V | Hardness |

|---|---|---|---|---|---|

| 0°C | |||||

| As Welded | 420 | 590 | 44 | HRc |