- PRODUCT SPECIFICATIONS

- PACKAGING

- Ask quotation

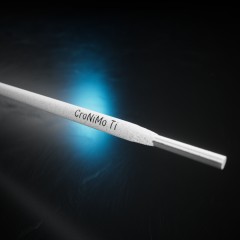

CEWELD® CroNiMo Ti is a rutile coated stick electrode of type E 20 10 3 R / E308Mo-16 with basic components for ferrite and austenitic joints and intermediate layers for weld claddings.

Mixed joints between structural, fine-grained structural and quenched and tempered steels with high-alloy Cr and CrNi(Mo) steels; austenitic manganese steels with each other and with other steels.

CEWELD® CroNiMo Ti is a rutile coated stick electrode of type E 20 10 3 R / E308Mo-16 with basic components for ferrite and austenitic joints and intermediate layers for weld claddings.

Mixed joints between structural, fine-grained structural and quenched and tempered steels with high-alloy Cr and CrNi(Mo) steels; austenitic manganese steels with each other and with other steels.

CEWELD® CroNiMo Ti has good corrosion resistance to seawater and general corrosion with excellent welding properties and self-releasing slag. Highly crack resistant.

W.Nr: 1.4311, 1.4401, 1.4404, 1.4408, 1.4571, 1.4573, 1.4580,1.4581, 1.4712, 1.4742, 1.4828,

X 12 CrNi 22 12, X5CrNiMo17-12-2, X2CrNiMo17-12-2, G-X5CrNiMo19-11-2, X6CrNiMoTi17-12-2, X10CrNiMoTi18-12, X6NiCrMoNb17-12-2, G-X5CrNiMoNb19-11-2

NFA 35-578 : Z 15 CN 24.13

ASTM/AISI : 304, 347, 309, 316, 316L, 316Ti, 316Cb

UNS: S31600, S31603, J92900, S31635, S31640

UGINE : NS 24, R 27. A, UGINOX 17-10 M, UGINOX 18-11 ML, UGINOX 17-11 MT

+ for dissimilar joints between low alloy/mild steels and stainless steels.

| Heat Treatment |

RP0,2 (MPa) |

Rm (MPa) |

A5 (%) |

Impact Energy (J) ISO-V | Hardness |

|---|---|---|---|---|---|

| RT | |||||

| As Welded | 420 | 600 | 35 | 70 | HRc |