- PRODUCT SPECIFICATIONS

- PACKAGING

- Ask quotation

Steam-valves, high temperature liquid pumps, hot cutting tools, exhaust valves.

Steam-valves, high temperature liquid pumps, hot cutting tools, exhaust valves.

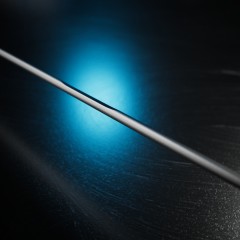

Outstanding alloy against abrasion, thermo-shock and corrosion combined with high temperatures. The weld deposit can be machined with tungsten tool tips and by grinding. The hardness of the weld deposit will degrees 16% at 300°C and about 30% at 600°C. The weld deposit is high heat resistant up to 900°C. DUR 6 offers a low coefficient of friction of 0.12 and exceptional resistance to galling. It has cavitation-erosion resistance ten times that of 304 stainless steel, DUR 6 can be used to protect bearing surfaces in non-lubricating conditions due to its resistance to metal-to-metal wear.

Stellite 6 alloy for, Steam-valves, high temperature liquid pumps, hot cutting tools, exhaust valves and seats

| Heat Treatment |

RP0,2 (MPa) |

Rm (MPa) |

A5 (%) |

Hardness |

|---|---|---|---|---|

| As Welded | 40 HRc |