- PRODUCT SPECIFICATIONS

- PACKAGING

- Ask quotation

Steam plants, vessel, waste plants, cementation steels, boiler works, tubes, heat exchangers

Steam plants, vessel, waste plants, cementation steels, boiler works, tubes, heat exchangers

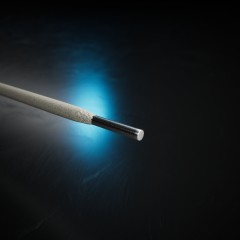

Rutile stick electrode for welding of steam production plants, steam pipes and similar joints made of Cr-Mo alloyed steel. The weld metal is resistant to working temperatures up to 550°C. as for similarly alloyed steels, quenched and tempered for cementation and nitrating.

Typ 1Cr 0,5Mo, ISO 15608: ~5,1

1.7335, 1.7262, 1.7728, 1.7218, 1.7225, 1.7258, 1.7354, 1.7357, 1.7205, 1.7218, 1.7225, 1.7228, 1.7254, 1.7262, 1.7335, 1.7337, 1.7350, 1.7354, 1.7357,

13CrMoV42, 13CrMo4-4, 13CrMo4-5, 15CrMo3, 15CrMo5, 13CrMoV42, 15Cr3, 16MnCr5, 20MnCr5, 15CrMo5, 24CrMo5, 25CrMo4, GS-22CrMo5, GS-22CrMo54, GS 17CrMo5-5, 16CrMoV4, 42CrMo4, 42CrMo4V, 41CrMo4V

ASTM A 182 Gr. F12; A 193 Gr. B7; A 213 Gr. T12; A 217 Gr. WC6; A 234 Gr. WP11; A335 Gr. P11, P12; A 336 Gr. F11, F12; A 426 Gr. CP12

| Heat Treatment |

RP0,2 (MPa) |

Rm (MPa) |

A5 (%) |

Impact Energy (J) ISO-V | Hardness |

|---|---|---|---|---|---|

| RT | |||||

| 660°C- 700°C 2h | 380 | 540 | 22 | 55 | HRc |