- PRODUCT SPECIFICATIONS

- PACKAGING

- Ask quotation

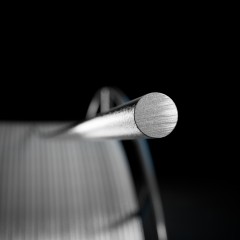

Shipbuilding, seawater evaporation plants, tubes, pump building, offshore etc. CEWELD® NiCu30Mn is suitable for dissimilar welding between Nickel 200-201, stainless steel, carbon steel, Inconel and Incoloy alloys, Nickel Copper and Copper nickel alloys.

Shipbuilding, seawater evaporation plants, tubes, pump building, offshore etc. CEWELD® NiCu30Mn is suitable for dissimilar welding between Nickel 200-201, stainless steel, carbon steel, Inconel and Incoloy alloys, Nickel Copper and Copper nickel alloys.

This Nickel - Copper weld metal has properties similar to “Monel 400”. It has good strength and resists corrosion in many media, including sea water, salts and reducing acids. The weld metal is not age hardenable and when used to join Monel K-500 it has lower strength then the base metal.

E Ni 4060 (NiCu30Mn3Ti)

2.4360, 2.4361, 2.4365, 2.4375, ( 2.0872, 2.0882, 2.0890 )

NiCu30Fe, NiCu30Al, G-NiCu 30 Nb, LC-NiCu 30 Fe,

ASTM B127, B163, B164, B165

UNS N04400

Monel 400, Monel R405, Monel K-500

Alloy K500 and dissimilar welding between these Alloys.

| Heat Treatment |

RP0,2 (MPa) |

Rm (MPa) |

A5 (%) |

Impact Energy (J) ISO-V | Hardness |

|---|---|---|---|---|---|

| RT | |||||

| As Welded | 300 | 450 | 30 | 70 | HRc |