- PRODUCT SPECIFICATIONS

- PACKAGING

- Ask quotation

New coatings on machine parts and shafts to increase life, rebuilding wornout parts etc. Layer thickness: approximately 0.1- 0.15 mm.

New coatings on machine parts and shafts to increase life, rebuilding wornout parts etc. Layer thickness: approximately 0.1- 0.15 mm.

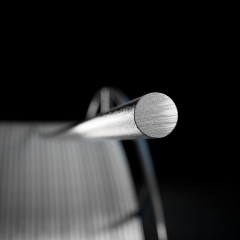

This alloy offers the highest bonding properties available for both the Flame spray process as the Arc Spray process. The wire has a high polished and clean surface to assure the best feeding and thermal spray properties. Sprayed layers of this material are-resistant to variation in high temperatures and are used as a buffer layer for all other spraying alloys. Hardness, coating macro: approximately HRc 22. Maximum working temperature: approximately 850 °C

Shafts, Clutches, Gliding surfaces, Valves, Bond coatings etc.

| Heat Treatment |

RP0,2 (MPa) |

Rm (MPa) |

A5 (%) |

Hardness |

|---|---|---|---|---|

| As Welded | 75 HB |