Strong Steel, Robust Connections: Welding Fine-Grain Structural Steel

In a world where sustainability and efficient resource utilization take center stage, high-strength steel emerges as a game-changer. High strength steel allows constructors to design lower weight constructions because plate thickness can be decreased.

therefor reduce of CO₂ emissions in vehicles cranes etc. is possible but, it also enhances load capacity because of minimizing own weight.

In this blog, we delve deeper into optimized production processes, such as thermomechanical rolling, and explore the role of fine-grain-forming alloy elements. Discover how these techniques makes impressive yield strengths up to 1300 MPa and excellent toughness values, even at low temperatures possible.

High-strength and high-strength fine-grained structural steels are those with a nominal yield strength >355MPa. The specific requirements for structural steels are given in the following parts of EN 10025

- Part 2: Non-alloy structural steels

- Part 3 Normalized/normalized rolled weldable fine grain structural steels

- Part 4: Thermomechanical rolled weldable fine grain structural steels

- part 6: High yield strength structural steels in quenched and tempered condition

AHSS stands for Advanced High Strength Steels and refers to modern techniques of the production of these kind of steels.

- Getting acceptable results as required high strength in combination with minimum impact values, in some cases down to -60°C

- In offshore applications the requirement for minimum impact values of the filler metal that has to meet 10% of the yield strength at the respective test temperature in J (i.e. 69J at -60°C for 690 MPa)

- Prefenting cracks (the biggest risk here are hydrogen-induced cracks)

- Prefenting hardness values that are higher than acceptable in the weld metal and HAZ

- Finding the right welding parameters to meet the requirements can be hard.

Hydrogen cracking in welded joints or HACC (Hydrogen Assisted Cold Cracking) is probably the biggest problem. According to the latest technology, HACC in welded steels is caused by three main interrelated factors:

- Hydrogen Cracking: Hydrogen concentration in the weld seam should be less than 5 ml/100g to prevent cracks.

- Residual Stresses: Local residual stresses due to thermal contraction during cooling can cause cracks.

- Crack-Prone Structures: Coarse grain structures in the heat-affected zone (HAZ) or weld metal can be prone to cracking.

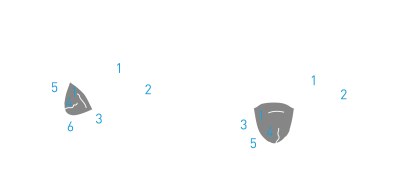

- Transverse crack in the weld seam

- Transverse crack in the HAZ

- HAZ transition crack

- Weld root Crack

- HAZ Root Crack

- Crack beneath the weld seam

Whenever the factors tensions, microstructure and hydrogen meet in an unfavorable constellation.

- Hydrogen: keep the hydrogen content as low as possible in the weld metal.

- Welding Method: Choose the appropriate welding method.

- Carbon Equivalent: Monitor the carbon equivalent to prevent crack behavior

- Preparation of the connection

- Chemical composition: Of base materials and filler metal

- Mechanical properties: Don't use inferrior base materials

- Heat input: Use the right welding parameters

- Cooling Time: Optimize the cooling time from 800°C down to 500°C (t 8/5).

- Preheating: Preheat temperature in accordance with the base materials to be used

- PWHT: Post weld heat treatment to reduce stress

A quick look at international standards and their limits.

| ISO | ASME (AWS) | JIS | AS/NZS | |

| Hydrogen levels | Diffusible weld metal hydrogen (ml/100g) | |||

| Controlled | ≤15 | ≤16 | ≤15,≤15,≤12 | ≤15 |

| Low | ≤10 | ≤8 | ≤10, ≤9, ≤7 | ≤10 |

| Very low | ≤5 | ≤4 | ≤6 | ≤5 |

The H2 levels are divided into steps of 5 or 4 ml/100g and are also reflected in the standard classifications of the filler materials. There are also standardized measurement methods for this, which are essentially based on two methods.

- Long measuring time 72-144 h

- Expensive

- No longer approved in all countries due to the use of mercury

- Fast (approx. 20-30 minutes at max. 400 °C)

- Simple

- Unobjectionable

- Software Support

The sources of hydrogen in welding can be seen very well in our graphic below.

Using the example of MAG welding, we would like to point out an essential, often underestimated, factor - stickout and its influence on the absorption of gases from the environment.

Factors of influence:

- Flux

- Liquids

- Air

- Surface contamination

N₂, O₂, and H₂ are the most common causes of cracks, hardness peaks and their influence on elongation and strength. This diagram shows the gas absorption in the weld metal depending on the stickout.

Long stick out

- Negative impact on N₂ / O₂

- Possitive influence on H₂

Short stick out

- Negative impact on H₂

- Positive impact on N₂ / O₂

This diagram gives a recommendation for a stickout of 15 - 20 mm for arc welding.

Parameters that affect the cooling time from 800°C down to 500°C (t 8/5)

The focus here must be on the correct selection of the welding process, the filler metal and the welding parameters. Achieving the optimal cooling time (t 8/5) during welding is the key to success. This can mean each welding seam should be considered individually to determine the correct welding parameters (current, voltage, welding speed).

Chemical composition of the base material determines the carbon equivalent. Normally this equivalent is given by the steel manufacturer or it can be calculated with two different formulas.

The two most common carbon equivalents are CE (for 0.05 – 0.25% C content) and CET (0.05 – 0.32% C content).

From our point of view, the CET formula is better suited for dealing with questions regarding cold crack behavior.

IIW-Formula

CET-Formula

(EN 1011-2 attachment C.3)

You can often find calculated CET values in the literature or the data sheets of steel manufacturers. This CET value in combination with the sheet thickness is used to determine the preheating temperature.

Min - Preheating temperatures (working temperatures) for welding processes with relatively low heat input (line energy Q ≈ 0.5 kJ/mm) as a function of the carbon equivalent CET of the base material and hydrogen content of the weld metal.

Min - Preheating temperatures (working temperatures) in welding processes with relatively high heat input (line energy Q ≈ 3.5 kJ/mm) as a function of the carbon equivalent CET of the base material and hydrogen content of the weld metal.

t ≤ 50: A= 4 x t, max. 50 mm

t > 50: A= 75 mm

Example of the working range of welding consumables

For steel with CET = 0.39 and different hydrogen contents (HD).

Widely waved

| Rm | 560 | MPa |

| Rp0,2 | 500 | MPa |

| A5 | 27 | % |

| CEV | 74 | J (-40°C ) |

Narrow waved

| Rm | 620 | MPa |

| Rp0,2 | 560 | MPa |

| A5 | 27 | % |

| CEV | 120 | J (-40°C ) |

Non waving

| Rm | 650 | MPa |

| Rp0,2 | 580 | MPa |

| A5 | 23 | % |

| CEV | 63 | J (-40°C ) |

We will be happy to help you select the right process for your application, the right CEWELD filler material and the appropriate parameters for an optimal welding result.